Steel coil vertical lifting equipment plays a crucial role in different industrial settings. Two typical application scenarios are the high - frequency large - span lifting in ports and the precision - rhythm matching in sheet metal processing centers.

In ports, the equipment is required to handle high - frequency large - span lifting tasks. With the continuous flow of steel coils in and out of ports, the equipment needs to be able to lift heavy loads quickly and accurately. It can reduce the time of each lifting operation by about 20%, which significantly improves the overall handling efficiency. This high - efficiency operation can also reduce the waiting time of cargo ships, saving a large amount of logistics costs. On average, it can help ports reduce the cost of each handling operation by about 15%.

In sheet metal processing centers, the key is to match the precision and rhythm of the production line. The equipment needs to ensure that the steel coils are accurately placed at the processing stations, and the error rate should be controlled within 0.5%. By using this equipment, the efficiency of coil replacement can be increased by more than 20%, which greatly improves the continuity of the production line and reduces the production cycle by about 10%.

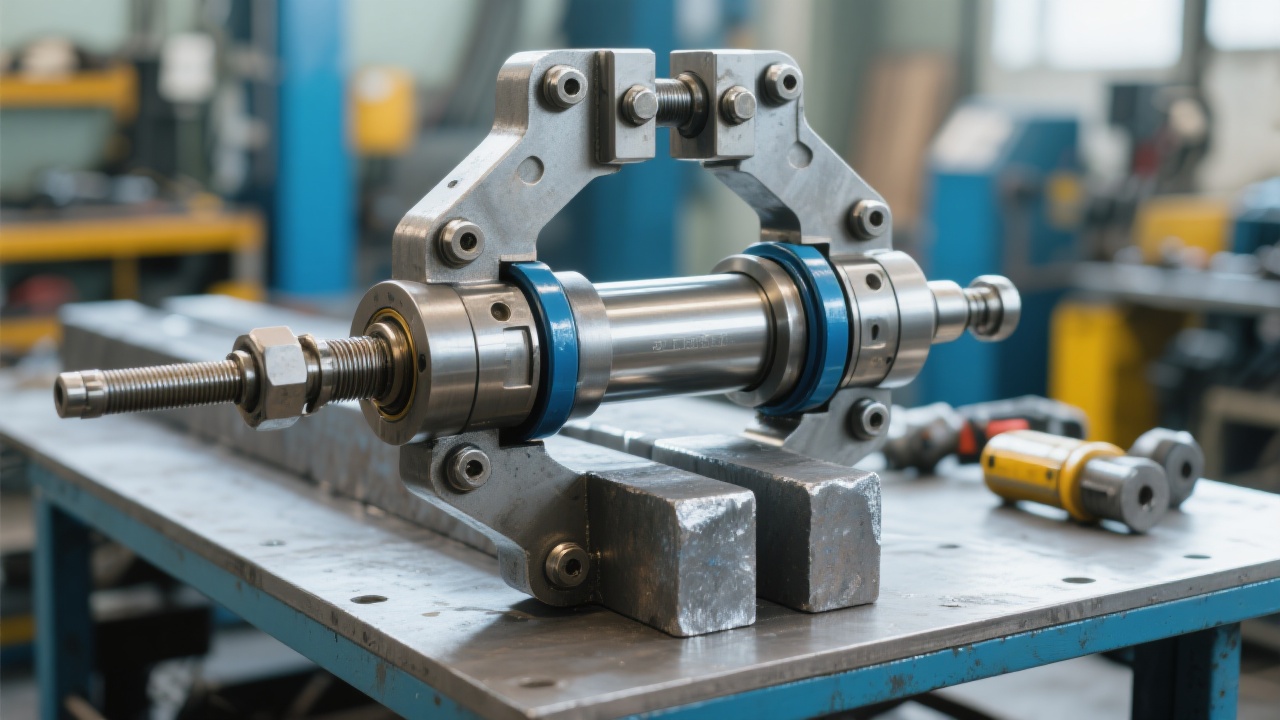

The structure and performance of steel coil vertical lifting equipment vary in different working conditions. In port operations, due to the large - span and high - frequency lifting requirements, the equipment usually has a more robust structure. Its hoisting mechanism can withstand a large amount of pulling force, and the anti - swing system can ensure the stability of the steel coil during the lifting process. Tests show that in port operations, the stability of the equipment can be maintained at more than 95%.

In sheet metal processing centers, the equipment needs to be more precise. It is often equipped with high - precision sensors and control systems to ensure accurate positioning. The positioning accuracy can reach within ±1mm, which meets the high - precision requirements of the processing center.

During the operation of the steel coil vertical lifting equipment, various problems may occur, such as mechanical wear, electrical system failures, etc. These problems can lead to equipment downtime, affecting production efficiency and safety.

The equipment has a series of advantages in adapting to different working conditions. For example, in port operations, its large - load capacity and high - stability structure can ensure continuous and efficient operation; in sheet metal processing centers, its high - precision positioning function can meet the needs of the production line.

A daily check list is essential for equipment maintenance. It includes checking the mechanical structure for cracks and wear, the electrical system for loose connections and insulation conditions, and the hydraulic system for oil leakage. Regular checks can detect potential problems in time and reduce the risk of equipment failure by about 30%.

The maintenance cycle of the equipment varies according to different parts. For example, the lubrication parts need to be lubricated every 100 operating hours; the inspection of the hoisting mechanism should be carried out once a month; and the overall performance test of the equipment should be carried out once a quarter.

When a fault occurs, a scientific fault diagnosis method is needed. By analyzing the fault symptoms, such as abnormal noise, abnormal vibration, and system alarms, combined with the operating data of the equipment, the cause of the fault can be accurately found. The accuracy of fault diagnosis can reach more than 90%.

In general, regular maintenance and scientific fault diagnosis are the keys to ensuring the normal operation of steel coil vertical lifting equipment. Equipment operators and maintenance personnel should strictly follow the maintenance process and check list to ensure the safety and efficiency of equipment operation.

| Maintenance Items | Ports | Sheet Metal Processing Centers |

|---|---|---|

| Mechanical Structure | Focus on checking large - load parts for wear and cracks | Focus on checking precision parts for wear and deformation |

| Electrical System | Pay attention to waterproof and moisture - proof, and check for loose connections | Pay attention to anti - interference, and check the accuracy of sensor signals |

| Hydraulic System | Check for oil leakage and the performance of hydraulic pumps | Check the cleanliness of hydraulic oil and the operation of valves |

In the context of the manufacturing industry's automation upgrade, steel coil vertical lifting equipment plays an important role in intelligent manufacturing transformation. It can be integrated with the factory's information management system, realizing real - time monitoring of equipment status, remote control, and intelligent scheduling. By using this equipment, the degree of automation of the production line can be increased by about 30%, which greatly improves the overall competitiveness of the enterprise.

If you want to learn more about the steel coil vertical lifting equipment and its maintenance details, you can click here to download our free PDF inspection form and get more professional guidance.